Q-Prime®

Our proprietary Q-Prime® thermal adhesive enhances flexible circuit thermal management to help your LED designs take shape.

Let LED designs take shape.

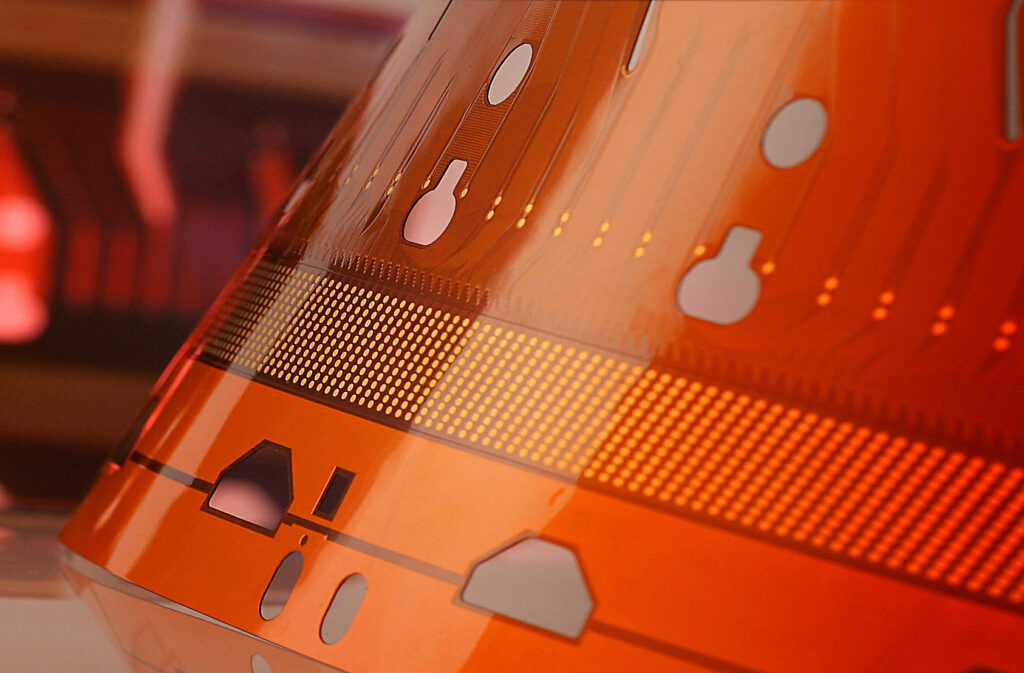

Designed specifically for high-current, thermal control applications requiring heat dissipation, Q-Prime® technology has been relied on throughout the automotive industry for over 30 years. Designed with heat conductive adhesive (Novaclad® / Novaclad® HDI), Q-Prime® enables attached components to run at cooler temperatures than traditional flex constructions.

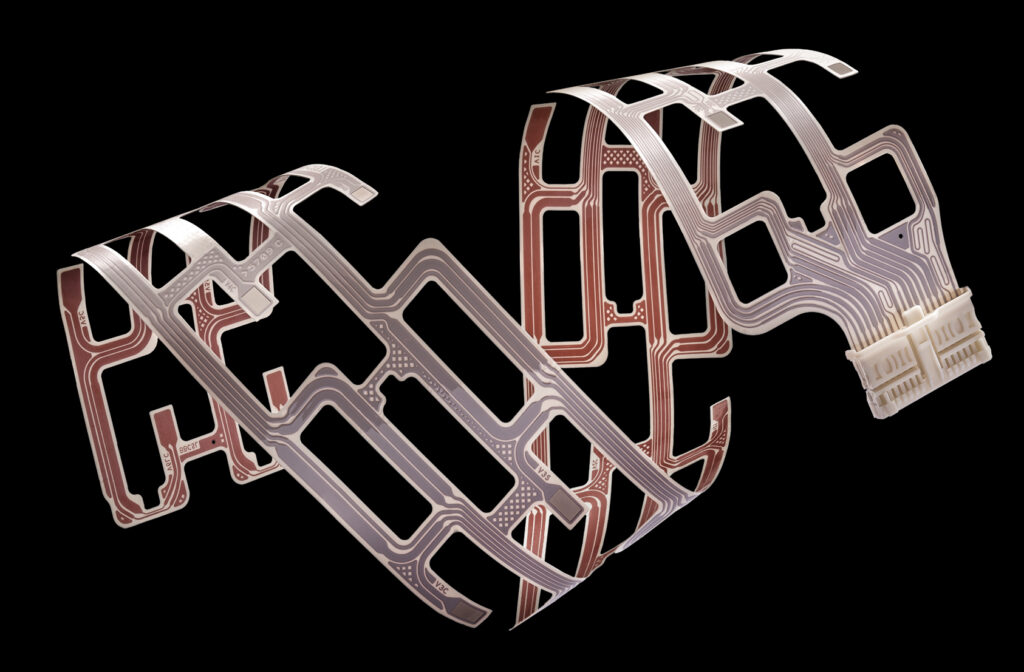

Q-Prime® flexible circuit technology is well suited for automotive applications, including headlamps, fog lamps, DRL, indicators, and HUDs. And with its ability to reduce cost, solve heat concerns, and deliver long-term reliability, Q-Prime® is redefining what’s possible for a range of LED applications across several industries.

Q-Prime® – Flexibility in thermal management

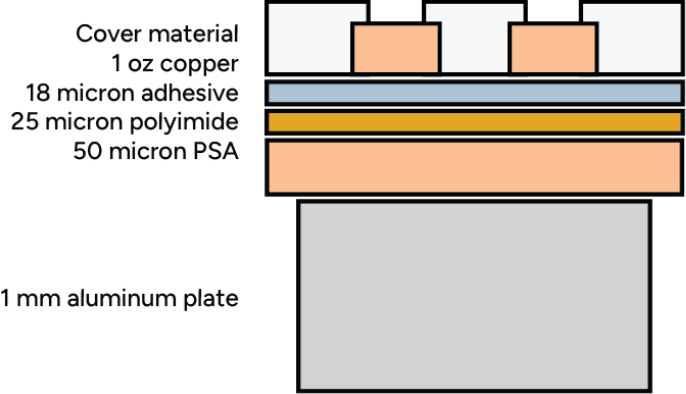

Flex on aluminum

Dielectric thermal impedance

°C-cm2/watt

4.5

Lateral thermal impedance

°C/watt-square

6†

Emissivity

0.3

Eff. radiative HTC

@ 30°C∆T,W/m2-k

2.1

Basis weight

grams per 100 cm2

31.3†

Low & mid power LEDs: Automotive interior, automotive exterior, troffers, structured luminaries

Q-Prime® 1300

Dielectric thermal impedance

°C-cm2/watt

1.3

Lateral thermal impedance

°C/watt-square

45

Emissivity

0.8††

Eff. radiative HTC

@ 30°C∆T,W/m2-k

5.7

Basis weight

grams per 100 cm2

7.1

Mid power LEDs: Automotive interior, automotive exterior, light bulbs, troffers, Cu-based heaters

Q-Prime® 2900

Dielectric thermal impedance

°C-cm2/watt

1.3

Lateral thermal impedance

°C/watt-square

72

Emissivity

0.8††

Eff. radiative HTC

@ 30°C∆T,W/m2-k

5.7

Basis weight

grams per 100 cm2

7.5

Mid power LEDs: Automotive interior, automotive exterior, light bulbs, troffers, Cu-based heaters

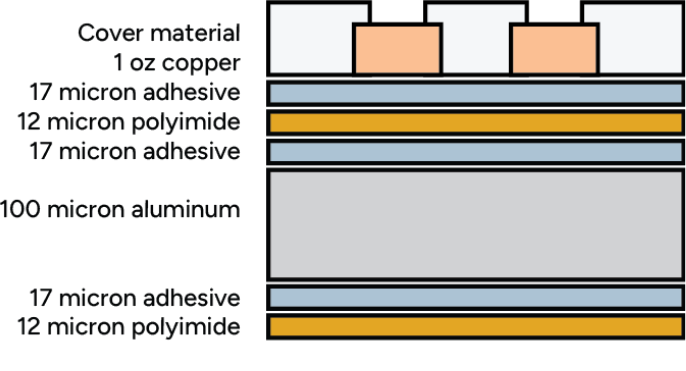

Q-Prime® NOVA

Dielectric thermal impedance

°C-cm2/watt

0.9

Lateral thermal impedance

°C/watt-square

72

Emissivity

0.8††

Eff. radiative HTC

@ 30°C∆T,W/m2-k

5.7

Basis weight

grams per 100 cm2

7.0

Mid & high power LEDs: Automotive head lamps, displays, high-intensity luminaries, light bulbs, Cu-based heaters

† based on 1 mm structural Al plate

†† with back cover layer

Q-Prime® tapes

Dielectric thermal impedance

°C-cm2/watt

0.2/1.3/1.1

Lateral thermal impedance

°C/watt-square

NA

Emissivity

0.8

Eff. radiative HTC

@ 30°C∆T,W/m2-k

5.7

Basis weight

grams per 100 cm2

0.3/0.7/0.5

Various & other: Enhanced flex-on aluminum, automotive lighting, flexible heaters, power electronics, temperature sensing

TECHNICAL SPECIFICATIONS

Q-Prime® 1300

Dielectric thermal impedance: 4.5°C-cm2/watt

Emissivity††: 0.8

Basis weight: 7.1 grams per 100 cm2

Q-Prime® 2900

Dielectric thermal impedance: 1.3°C-cm2/watt

Emissivity††: 0.8

Basis weight: 7.5 grams per 100 cm2

Q-Prime® NOVA

Dielectric thermal impedance: 1.3°C-cm2/watt

Emissivity††: 0.8

Basis weight: 7.0 grams per 100 cm2

Q-Prime® tapes

Dielectric thermal impedance: 0.2°C-cm2/watt, 1.3°C-cm2/watt, 1.1°C-cm2/watt

Emissivity: 0.8

Basis weight: 0.3 grams per 100 cm2, 0.7 grams per 100 cm2, 0.5 grams per 100 cm2

†† with back cover layer

APPLICATIONS

Automotive and transportation

Commercial transportation

CAPABILITIES

Greater design flexibility

Improved thermal performance

Reliable dimensional stability

Reduced weight and space

Lower overall system cost

- Q-Prime® 1300

- Dielectric thermal impedance: 4.5°C-cm2/watt

- Emissivity††: 0.8

- Basis weight: 7.1 grams per 100 cm2

- Q-Prime® 2900

- Dielectric thermal impedance: 1.3°C-cm2/watt

- Emissivity††: 0.8

- Basis weight: 7.5 grams per 100 cm2

- Q-Prime® NOVA

- Dielectric thermal impedance: 1.3°C-cm2/watt

- Emissivity††: 0.8

- Basis weight: 7.0 grams per 100 cm2

- Q-Prime® tapes

- Dielectric thermal impedance: 0.2°C-cm2/watt, 1.3°C-cm2/watt, 1.1°C-cm2/watt

- Emissivity: 0.8

- Basis weight: 0.3 grams per 100 cm2, 0.7 grams per 100 cm2, 0.5 grams per 100 cm2

- †† with back cover layer

- Automotive and transportation

- Commercial transportation

- Industrial

- Greater design flexibility

- Improved thermal performance

- Reliable dimensional stability

- Reduced weight and space

- system

- Q-Prime® product bulletin

We’re here to help.

Connect with our engineers to find the right solution for any challenge.