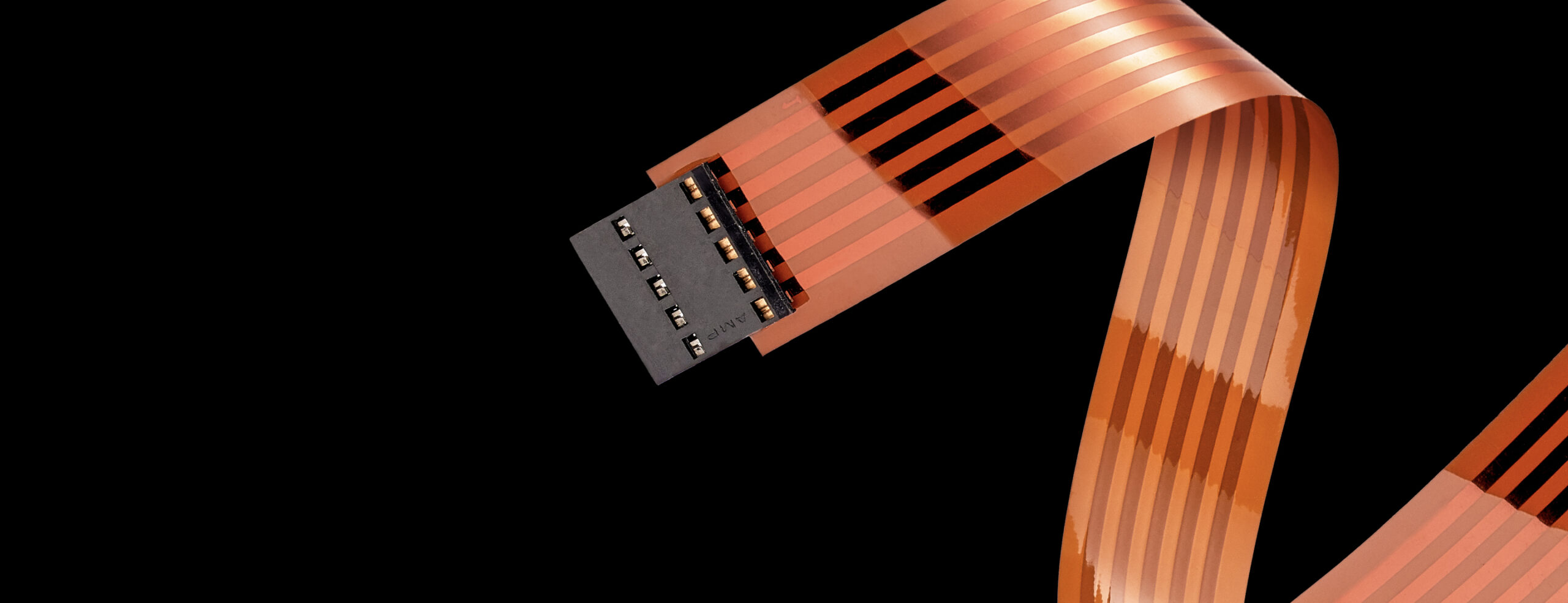

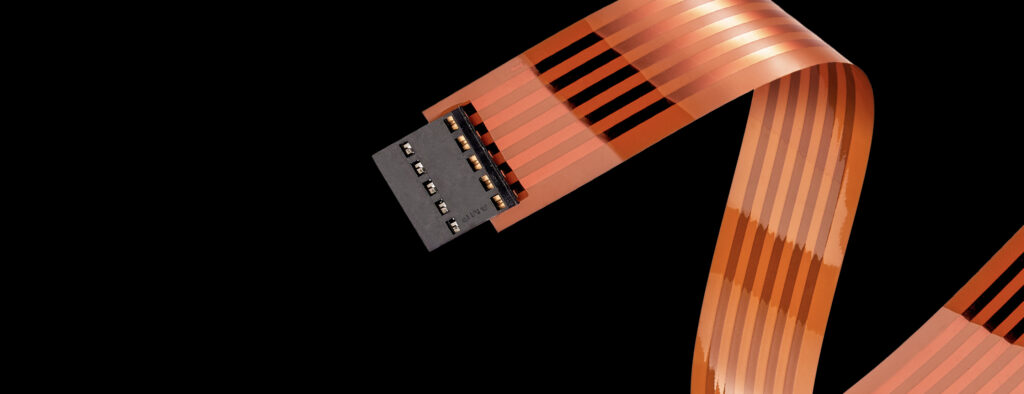

Flexible printed circuits

Enabling more performance and design freedom for compact electronic applications.

Flexible printed circuits

With interconnect solutions that bend, fold, and can be configured to meet your needs, our flexible circuit offerings help your designs take shape.

Whether it’s improving thermal management and aesthetics or reducing weight and assembly costs, we can help you overcome the biggest design and packaging challenges facing the automotive, medical, industrial, aerospace, and defense industries.

Putting innovation on display.

From capacitive touch and displays to heaters and shielding, our transparent circuit solutions are redefining what’s possible for a range of applications.

See LEDs in a whole new light.

Our proprietary Q-Prime® solutions enhance reliability, lower costs, and enable design flexibility for LED applications that rigid circuit boards can’t achieve.

We’re here to help.

Connect with our engineers to find the right solution for any challenge.